How is MOQ Determined in Cosmetic Manufacturing?

- 동훈 Jason 임

- Feb 2

- 2 min read

What is MOQ?

MOQ (Minimum Order Quantity) is the minimum production quantity set by manufacturers to ensure cost efficiency and operational feasibility. In cosmetic manufacturing, MOQ is determined by factors such as liquid formulation and packaging components, making it a crucial aspect of production planning.

Why is MOQ Important for Brands and Manufacturers?

Importance of MOQ for Brands

Cost Reduction: Ordering in bulk helps lower per-unit costs.

Inventory Management: Too high an MOQ can lead to excess stock, while too low an MOQ may hinder production feasibility.

Market Testing: Setting an appropriate MOQ allows brands to test new products in the market effectively.

Importance of MOQ for Manufacturers

Production Efficiency: A minimum production quantity ensures smooth operation of manufacturing equipment.

Raw Material Procurement: Bulk purchasing reduces material costs.

Process Stability: Proper MOQ settings prevent inefficiencies in production workflow.

How is MOQ Determined in Cosmetic Manufacturing?

1. Liquid MOQ Determination

The MOQ for cosmetic liquid formulations depends on the capacity of manufacturing tanks. For instance, a 300kg mixing tank typically requires at least two-thirds of its capacity (around 200kg) to function properly. This minimum capacity dictates the smallest feasible production batch.

2. Packaging MOQ Determination

Packaging MOQ is dictated by the policies of packaging manufacturers. Cosmetic manufacturers must comply with these policies when ordering packaging components.

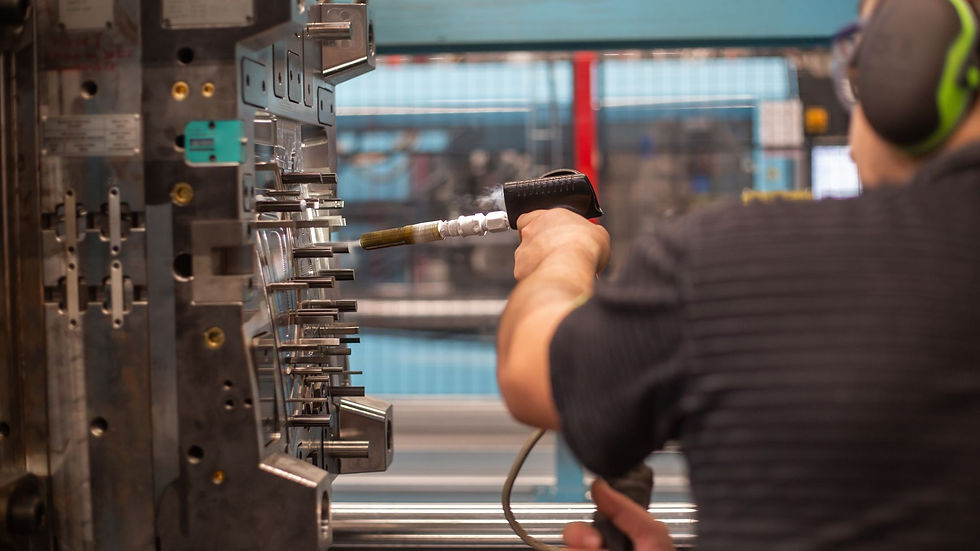

Free Mold vs. Custom Mold

Free Mold: Using existing molds owned by the manufacturer allows lower MOQs, typically ranging from a few hundred to 3,000-5,000 units.

Custom Mold: Creating a new mold requires a larger MOQ, usually a minimum of 10,000 units.

These factors collectively determine the overall MOQ set by cosmetic manufacturers, impacting the production strategies of brands.

Conclusion

MOQ in cosmetic manufacturing is not just a fixed number but a result of multiple factors, including liquid batch size and packaging availability. Brands must carefully consider MOQ to optimize costs and market strategy, while manufacturers set MOQ levels to maintain production efficiency.

Comments